How to Choose the Best Plenum-Rated Pipe and Duct Insulation

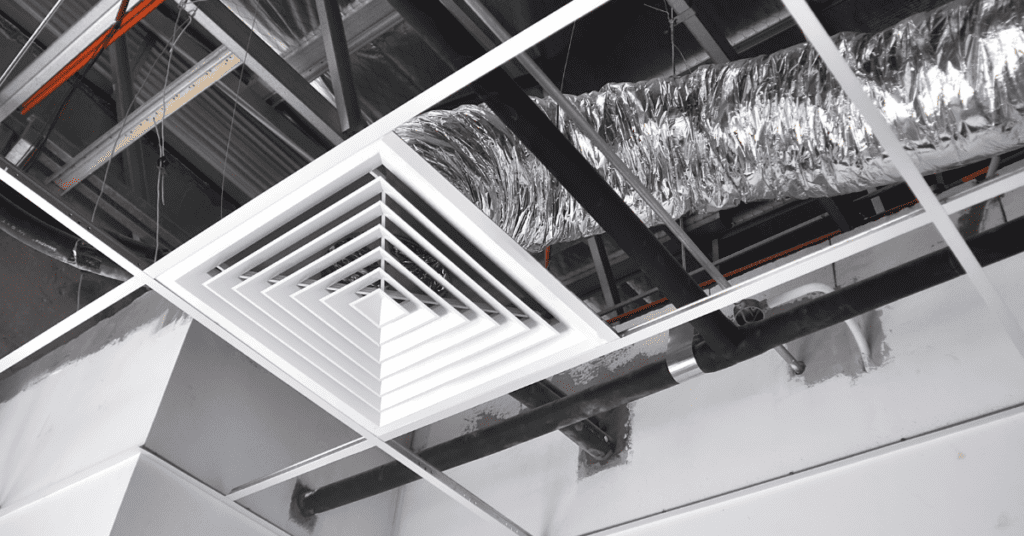

Plenum spaces in buildings are designed to discreetly house building systems such as HVAC equipment & return airflow, pipe runs, and digital cables. Although air plenums are typically out-of-sight, typically located above ceiling grids or in under-floor systems, mechanical design (i.e. plenum rated insulation) are critically important to ensure the safety of building occupants and the building itself.

Since air plenums house HVAC systems that require airflow, they present an oxygen-rich environment in which fire and smoke has the potential to spread through the plenum and into occupant spaces (through ductwork for example) risking life safety. It’s critical that building materials installed within building air plenums, such as plenum rated insulation, suppress and do not propagate flame spread and smoke development.

How Do You Identify Plenum Rated Insulation?

Most U.S. building codes reference the International Mechanical Code (IMC) which provides specific requirements for acceptable building components to be specified and installed in plenums. The 2018 IMC Section 602.2.1.8 “Pipe and duct insulation within plenums” specifies the following requirements:

“Pipe and duct insulation contained within plenums, including insulation adhesives, shall have a flame spread index of not more than 25 and a smoke-developed index of not more than 50 when tested in accordance with ASTM E84 or UL 723, using the specimen preparation and mounting procedures of ASTM E2231. Pipe and duct insulation shall not flame, glow, smolder or smoke when tested in accordance with ASTM C411 at the temperature to which they are exposed in service. The test temperature shall not fall below 250°F(121°C). Pipe and duct insulation shall be listed

and labeled.”

This is the most accurate definition of plenum rated insulation so let’s break this down. First and foremost, plenum rated insulation must pass ASTM E84 Standard Test Method for Surface Burning Characteristics of Building Materials or UL 723 Standard for Test for Surface Burning Characteristics of Building Materials. Essentially, ASTM E84 and UL 723 standards are identical in that they utilize the same test method. The flame spread index must be not more than 25, and the smoke developed index must not be more than 50. This is what is commonly referenced as “25/50” or “25/50-rated”.

Secondly, plenum rated insulation shall not flame, glow, smolder or smoke when tested according to ASTM C411, and the continuous test temperature shall not fall below 250°F (121°C).

Finally, a more recent IMC requirement of plenum rated insulation is that it be “listed and labeled”. What does this mean? Listed means that the manufacturer’s plenum rated insulation is listed on a nationally-recognized test lab’s (NRTL) website under their “listing directory.” Labeled means that the manufacturer’s packaging references the nationally-recognized test lab’s logo. IMC’s listing & labeling requirements specify that the NTRL must perform “periodic” inspections of the manufacturer’s processes and products. Listing & labeling ensures that plenum rated insulation manufacturers consistently comply with the requirements over time as opposed to a single test report.

Aeroflex’s Aeroflex® brand of plenum rated insulation passes ASTM E84 25/50 up to 2” [50mm] thick. Aeroflex also is considered “self-extinguishing” per ASTM D635 Standard Test Method for Rate of Burning and/or Extent and Time of Burning of Plastics in a Horizontal Position. Since our EPDM formula has an upper continuous service temperature of 257°F (125°C), it meets ASTM C411.

Aeroflex plenum rated insulation will soon be listed on our nationally-recognized test agency’s website and labeled as required. Presently, all Aeroflex packaging references compliance with ASTM E84, and the trademark on our pre-formed pipe insulation does as well.

To learn more about Aeroflex USA plenum rated insulation solutions, please click here.

Sources:

https://codes.iccsafe.org/content/IMC2018P3/chapter-6-duct-systems#IMC2018P3_Ch06_Sec602

https://codes.iccsafe.org/content/IMC2018/chapter-6-duct-systems#IMC2018_Ch06_Sec604